Measurement service

Our Offering:

High-precision dimensional inspection

We provide high-precision dimensional inspection both in our accredited laboratories and directly in your production environment.

With stationary coordinate measuring machines (CMM), we achieve micrometre-level accuracy for demanding components.

Our portable CMM arms enable reliable 3D measurements even in challenging production conditions.

Stationary CMM in accredited laboratory

For maximum accuracy, we use our stationary CMM machines in accredited laboratories.

We measure components up to 1,000 × 1,000 × 1,000 mm with a measurement uncertainty of U = (5 + L / 250) μm, k = 2.

All measurements are performed in compliance with ISO/IEC 17025.

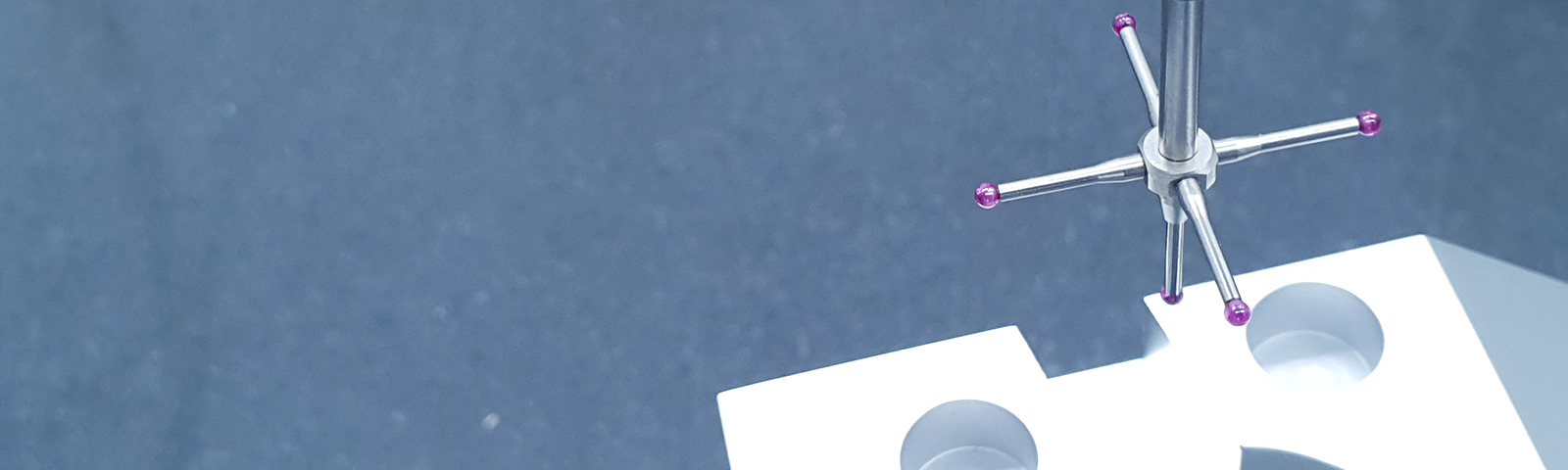

Touch-trigger probes ensure high accuracy and allow measurement of complex geometries that are difficult to reach with optical methods.

They also eliminate noise that can sometimes occur with optical measurements.

Portable CMM for on-site measurement

When you need fast and accurate results directly in your production facility, we use our portable CMM arms.

They are hand-operated and require no predefined measurement points, enabling flexible and efficient measurement.

Each CMM arm has a reach of 1.8 metres and a theoretical measuring sphere of 3.6 metres.

The measurement uncertainty is U = ± 0.086 mm, k = 2, ensuring reliable results even in demanding environments.

Reverse engineering

Our measurement services allow you to digitise and archive the geometry of critical components for future needs.

We can also create technical documentation when drawings are missing.

In collaboration with our experienced metallurgists, we can determine key material properties such as:

- Hardness

- Tensile strength

- Impact toughness

- Chemical composition

Certifications and Accreditations

Our laboratories are accredited by the national accreditation body in each country.

Always audit-ready with MIO™

Optimize your workflow with the reliable Metech Instrument Organizer, MIO™

More than 1.000 satisfied customers have digitalized their instrument calibration using MIO™.

MIO™ offers real-time tracking of calibration status, instrument history, and certificates, ensuring compliance and audit readiness. Easily book calibrations and services online. MIO™ can be utilized regardless of whether you perform your calibrations in-house or use an external supplier for instrument calibration.

“We chose Element Metech because they help us with our needs as quickly as possible. Even if we have our own calibration date base, you send us reminders about the next calibration time so that we don’t miss any. If we need your calibration system MIO where you register all calibration certificates of our equipment, then we have access to that.”

Damir Jonjic

Senior Mechanical Engineer, Cytiva

Talk to our experts

We offer qualified services in metrology and calibration to industries and authorities with stringent quality requirements, including aerospace, defense, manufacturing, automotive and engineering industries, as well as medical technology.

Sebastian Brandtberg

Contact me

What is a coordinate measuring machine (CMM) and what is it used for?

A coordinate measuring machine (CMM) is a device used to measure the geometric characteristics of an object.

It is used to verify and inspect the dimensions and tolerances of components, and can measure size, shape and position with high precision.

What types of objects can be measured with a coordinate measuring machine (CMM)?

A coordinate measuring machine (CMM) can measure a wide range of objects, from simple geometric shapes to more complex components.

Common examples include fixtures, prototypes, reference parts and production parts that require high accuracy in size and form.

What is the difference between a stationary and a portable coordinate measuring machine (CMM)?

A stationary coordinate measuring machine (CMM) is typically used in a laboratory or other controlled environment, offering the highest possible measurement accuracy. A portable coordinate measuring machine (CMM) is a mobile measuring arm that can be used directly on-site in production environments, providing flexible measurement capabilities.

What measurement uncertainty can I expect from a coordinate measuring machine (CMM)?

The measurement uncertainty for a stationary coordinate measuring machine (CMM) is typically

<strong>U = (5 + L / 250) μm, k = 2</strong>, while a portable CMM arm has a measurement uncertainty of <strong>U = ± 0.086 mm, k = 2</strong>. This ensures very high precision when measuring various components, depending on the application and location.

More information

Service

Metech Instrument Organizer, MIO™

Our webbased instrument organizer provides real-time overview of status, history and certificates.

Customer case

Reliable and high-quality calibration for Cytivas instruments and equipment

Researchers, academia, and biopharma undertake...

Education

Courses & Webinars

Our training courses and webinars provide practical insights into calibration and metrology.

News

Well-Attended Event on Industrial Cooperation for Strengthened Total Defence

Increased collaboration between civil and...

Customer case

Ensuring uptime and precision through calibration

At Toyota Material Handling Manufacturing...

Service

Business solutions for optimized measuring equipment management

Element Metech provides a comprehensive range of business calibration solutions.

News

Element Metech Expands and Inaugurates Its Second Mobile Calibration Lab

Element Metech’s new mobile calibration...

Service

Outsourcing

Handling calibration internally is often both time-consuming and resource-intensive. By outsourcing calibration, it becomes a smoother process, with lower costs and measurement results you can always trust.

Why choose Element as your calibration partner?

Our laboratories are accredited by the national accreditation body in each country. Element Metech holds one of the widest ranges of calibration accreditations in Europe.